|

|

Post by mrmotors on Oct 4, 2014 22:06:16 GMT -6

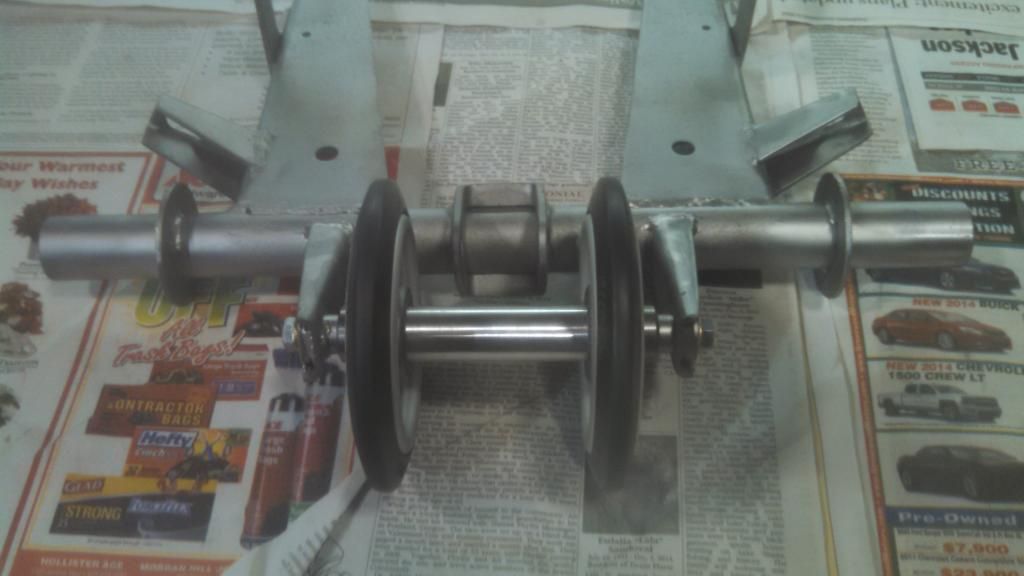

I have a pretty nice 4 banded track I am going to use in my F/A, the problem seemed to be getting idler wheels. I decided to make them. This is the 1st one made from 7075 aluminum and I am going to take it to the rubber guy and have a 1/2" layer of rubber put on the face of it. I'm going to take one of the smaller NOS idlers I have so he can get the rubber composition from it. If that all works out, I'll make 3 more and have the same done. This is all hand machine work, lathe and mill, no CNC stuff. I have a pretty nice 4 banded track I am going to use in my F/A, the problem seemed to be getting idler wheels. I decided to make them. This is the 1st one made from 7075 aluminum and I am going to take it to the rubber guy and have a 1/2" layer of rubber put on the face of it. I'm going to take one of the smaller NOS idlers I have so he can get the rubber composition from it. If that all works out, I'll make 3 more and have the same done. This is all hand machine work, lathe and mill, no CNC stuff. |

|

|

|

Post by mrmotors on Oct 4, 2014 22:13:32 GMT -6

I got the correct magnesium railed suspension. The rails are a bit tough, straightened them out in the press and have been welding them up. Have one about 1/2 done, still needs a bit more work on it. I have bought 4 magnesium bars and am going to have them machined into the slides. I don't have the equipment to roll it or machine the groove in the bottom after it's rolled into shape. If it was all flat work, that's not a problem. They need to be rolled first and then machined. If they are machined first, rolling the arch in it would crush the groove on the bottom. I got the correct magnesium railed suspension. The rails are a bit tough, straightened them out in the press and have been welding them up. Have one about 1/2 done, still needs a bit more work on it. I have bought 4 magnesium bars and am going to have them machined into the slides. I don't have the equipment to roll it or machine the groove in the bottom after it's rolled into shape. If it was all flat work, that's not a problem. They need to be rolled first and then machined. If they are machined first, rolling the arch in it would crush the groove on the bottom. |

|

|

|

Post by mrmotors on Oct 26, 2014 11:52:50 GMT -6

The idler wheels are pretty much done. A few more small things to do. The idler wheels are pretty much done. A few more small things to do. |

|

|

|

Post by red19lite on Oct 26, 2014 18:05:36 GMT -6

man those look great, kevin

|

|

|

|

Post by mrmotors on Oct 26, 2014 19:32:25 GMT -6

Thanks Kevin, appreciate it.

|

|

|

|

Post by 74nitro2 on Oct 27, 2014 4:44:30 GMT -6

Really nice work.  |

|

|

|

Post by racingelvis on Oct 27, 2014 11:05:02 GMT -6

very impressive!!! love it mike,.......

|

|

|

|

Post by mrmotors on Nov 2, 2014 23:29:49 GMT -6

|

|

|

|

Post by mrmotors on Nov 2, 2014 23:32:13 GMT -6

|

|

|

|

Post by mrmotors on Nov 2, 2014 23:38:35 GMT -6

Had to change the plan on the slide rails. I have done the machine work and this is the 1st "blank" so to speak. We think we have figured out how to arch them without crushing the groove for the slide. Got the learning curve down on the machining so once we get the bending proven I will make the other 3. Had to change the plan on the slide rails. I have done the machine work and this is the 1st "blank" so to speak. We think we have figured out how to arch them without crushing the groove for the slide. Got the learning curve down on the machining so once we get the bending proven I will make the other 3. |

|

|

|

Post by racingelvis on Nov 3, 2014 11:07:19 GMT -6

wow, that's awesome work right there mike, looks great. cant wait to see what they look like when there done!!

|

|

|

|

F/A stuff

Nov 3, 2014 14:37:21 GMT -6

via mobile

Post by mrmotors on Nov 3, 2014 14:37:21 GMT -6

Me too Bill, I hope we don't mash the channel arching them....magnesium bars are a bit pricey!!

|

|

|

|

Post by Ruppsforever on Nov 3, 2014 16:57:44 GMT -6

AWESOME !!!!!

|

|

|

|

Post by mrmotors on Jan 2, 2015 22:35:14 GMT -6

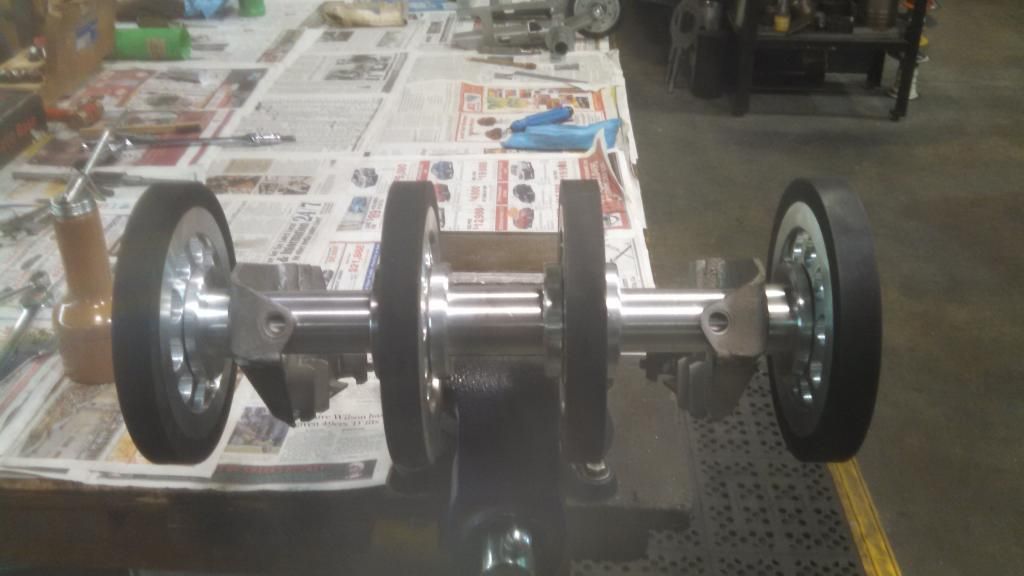

I finally outlasted this little bugger. I've found I have a combination of several parts in this suspension which is OK, it will work fine. I cut this thing apart and welded several things back together on it. It was crooked and twisted a bit. Had to build an axle set up to get the correct center to center spacing for the wheels to use the 4 band track. Thank You to Josh and Joe Marshall for giving me info and measurements from their sleds. I finally outlasted this little bugger. I've found I have a combination of several parts in this suspension which is OK, it will work fine. I cut this thing apart and welded several things back together on it. It was crooked and twisted a bit. Had to build an axle set up to get the correct center to center spacing for the wheels to use the 4 band track. Thank You to Josh and Joe Marshall for giving me info and measurements from their sleds. |

|

|

|

Post by mrmotors on Jan 2, 2015 22:40:01 GMT -6

These are the wheels I made from the earlier pic's. I machined a new axle shaft as well as the spools and spacers to get all the centers correct for the track. Been a lot of work to get this far. All I have left is the drill and thread the holes for the tensioner bolt's. I'm going to get a lot of this stuff hard anodized for additional corrosion and surface protection. Now, if the magnesium slide rails can be bent without mucking them up we'll be good. These are the wheels I made from the earlier pic's. I machined a new axle shaft as well as the spools and spacers to get all the centers correct for the track. Been a lot of work to get this far. All I have left is the drill and thread the holes for the tensioner bolt's. I'm going to get a lot of this stuff hard anodized for additional corrosion and surface protection. Now, if the magnesium slide rails can be bent without mucking them up we'll be good. |

|

|

|

Post by magnumed on Jan 3, 2015 7:51:18 GMT -6

Looks very nice. The magnesium rails will be tricky I'm sure. Have you ever tig welded the magnesium?

|

|

|

|

Post by mrmotors on Jan 3, 2015 12:08:43 GMT -6

Hi Ed, Yes I've welded magnesium, it's not all that different than welding aluminum. It's a bit "mushier" and requires pretty good temp control. Rockmount, others as well, make the rod for it.

|

|

|

|

Post by magnumed on Jan 3, 2015 12:44:14 GMT -6

Thanks, I'm going to try it soon once I get some rod and material.

|

|

|

|

Post by tmf on Jan 4, 2015 19:27:31 GMT -6

great work ! love hand machined parts .

Thats what a good machinist did back in the day.

Seems to be a dieing art / skill with so much cnc work.

|

|

|

|

Post by mrmotors on Jan 4, 2015 20:01:24 GMT -6

That is very true, fabricators/craftsmen are a dying breed. Most of this stuff nowadays, if you know computer programming and can read a blueprint that's all it takes. It takes me longer to machine it, or weld it or cut something up to make it into something else, but I think I have a greater sense of accomplishment in doing that. Programing a computer to make it perfect is cheatin', to make it accurately by hand is an artform.

|

|